- Product Name: Horizontal Induction Hardening and Tempering Machine

- Release Date: 2017-12-13

- Introductions:

Horizontal Induction Hardening and Tempering Machine......

- Details

1. Usage:

Horizontal Quenching Machine Tool is used to improve production method, productive efficiency and product quality; lower down work force cost and electricity cost by displacing the labor with equipment.

2.Principle:

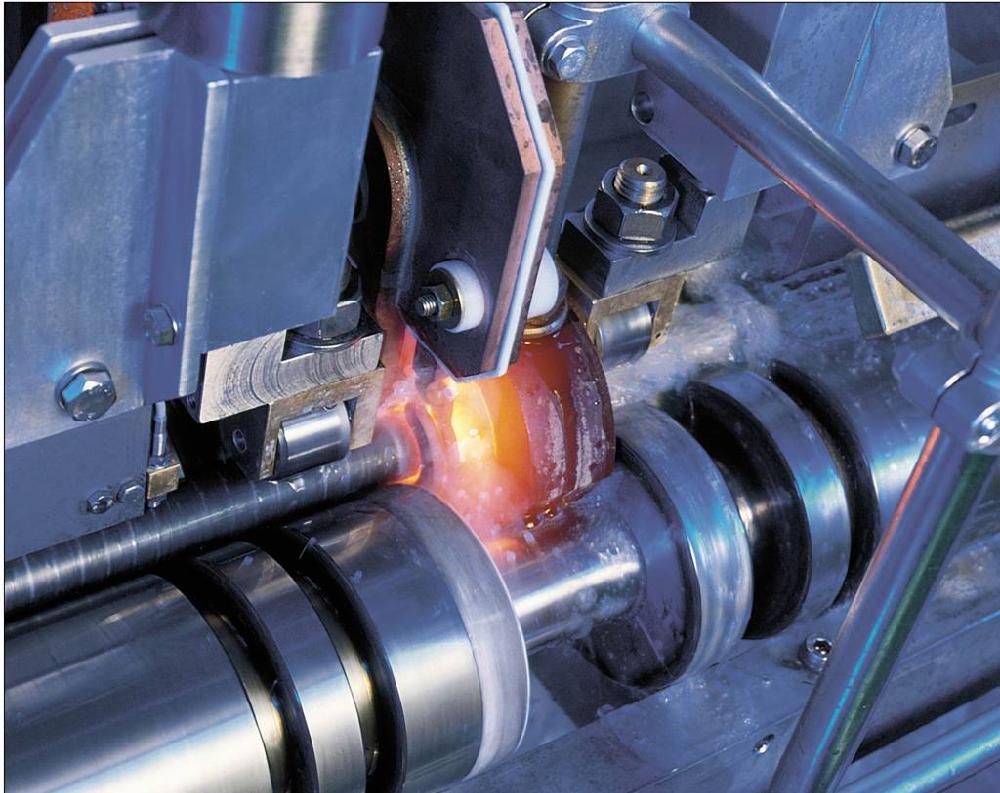

Horizontal Quenching Machine Tool adopt automation feed discharge, with Servo system to position, with stainless steel wheel to drive and rotate, with IGBT induction heating power to quench and temper.

3. Working process

Start→auto feeding→auto driving→auto heating and quenching→auto tempering→auto discharging→enter material case

4. Working range and work efficiency

A: This machine is used for steel rod quenching and tempering heat treatment;

B: Steel rod diameter range:Φ10-30mm(customized);

C: Steel rod length range: 100-500mm;

D: Hardening depth: 0.3-0.8mm

E: Efficiency: 4000pcs per day.

5. Structure description

1) Main machine frame is made of national standard polished material, and stainless steel and alloy materials.

2)Servo system:Working parts adopt with Japan Panasonic servomotor, rotating parts adopt Japan Panasonic adjustable motor, to protect the precision and the usage life of the machine.

3) Pneumatic part: all parts are made in Taiwan.

4) Electrical control system: PLC control touch screen adopt with Panasonic products, Japan Omron relay, France Schneider operation knob with stable quality.

5) Induction power:

5.1 Hardening induction heating power: BJG-40AB (40KW, 400Khz) IGBT model:

|

Model |

BJG-40KW |

Max work power |

40kw |

|

Input voltage |

Three phase 380V 50/60HZ |

Input frequency |

400KHZ |

|

Input control |

Constant current |

Load rate |

100% |

|

Constant power |

Water pressure |

>0.2mpa |

|

|

Input current |

200-2400A |

Air pressure |

>0.4mpa |

|

Heating current |

300-2400A |

Enter water temperature |

<35℃ |

|

Connect pipe length |

1.5 meter(customized max length: 6 meters) |

||

|

Preservation current |

300-2400A |

Preservation time |

1-99second |

|

Heating time |

1-99 second |

Ground |

4Ω |

5.2 Tempering induction heating power: BJ-60AB (60KW.30-80khz) IGBT model

|

Model |

BJ-60KW |

Max work power |

60kw |

|

Input voltage |

Three phase 380V 50/60HZ |

Input frequency |

30-80KHZ |

|

Input control |

Constant current |

Load rate |

100% |

|

Constant power |

Water pressure |

>0.2mpa |

|

|

Input current |

200-4200A |

Air pressure |

>0.4mpa |

|

Heating current |

300-3600A |

Enter water temperature |

<35℃ |

|

Connect pipe length |

1.5 meter(customized max length: 6 meters) |

||

|

Preservation current |

300-3600A |

Preservation time |

1-99second |

|

Heating time |

1-99 second |

Ground |

4Ω |

Horizontal Quenching Machine Tool adopt automation feed discharge, with Servo system to position, with stainless steel wheel to drive and rotate, with IGBT induction heating power to quench and temper.

- 【Print】

- 【Collection】

- 【Return】

-

HOTLINE:18666882320

-

QQ ONLINE:

-

MAILBOX:

-

WEBSITE:

Mobile: +86-186-6688-2320

Dongguan BEIJIASEN industrial co., LTD Support by: HENG DIAN

© 2017 BEIJIASEN.ALL Rights Reserved